🦾 What You Need to Know About Robot Safety Standards

A comprehensive overview of navigating safety standards and achieving compliance in Robotic Systems.

As more industries adopt robotics, ensuring the safety of these systems is becoming critical. Meeting protection standards doesn’t just protect workers—it also guarantees the reliability of robotic systems, especially when humans and robots share the workspace.

The International Organization for Standardization (ISO) develops global safety standards in collaboration with organizations like the International Electrotechnical Commission (IEC), requiring approval from most member countries (at least 75% of member bodies), ensuring consistency across industries. ISO standards help companies meet stringent safety requirements, especially in human-robot interactions.

Understanding CE Marking and ISO Standards

Although ISO standards are international and can be adopted by any country or organization globally, obtaining CE Marking is essential to legally operate robotic systems in Europe. This certification proves that the system meets crucial safety, health, and environmental standards. For robotic installations, CE Marking shows that the system has undergone protection assessments, reducing risks and ensuring reliable performance.

In tandem, ISO standards define global safety requirements for industrial robots and collaborative robots.

Collaborative Robots and Safe Human-Robot Interaction

In collaborative environments where robots and humans work side by side, safety mechanisms like power and force limiting become crucial. Cobots present unique safety challenges that require specialized standards like ISO/TS 15066 to ensure safe interactions.

ISO/TS 15066 provides guidelines for these robots to ensure that any accidental contact remains within safe force thresholds, minimizing the risk of injury. These cobots are designed with features like speed and separation monitoring, ensuring that their movements slow down or stop when a human enters their workspace or gets close to touching them.

Key ISO Standards for Robotic Installations

ISO 10218: This standard outlines safety requirements for industrial robots, focusing on design, construction, and operational safety. It ensures that robots are equipped with protective measures to mitigate potential hazards during operation.

ISO/TS 15066: This technical specification focuses on collaborative robots and their operation in shared workspaces. It outlines safety requirements specific to cobots, including limits on force and speed during human-robot interactions to prevent injuries from accidental contact.

ISO 3691-4: Specifically related to driverless industrial trucks, this standard applies to autonomous mobile robots, which are becoming increasingly prevalent in industrial settings.

Machinery Directive 2006/42/EC: This directive defines the safety requirements for machinery, including robots, ensuring that all installations are safe to use and compliant with European safety laws.

Achieving Compliance

Achieving and maintaining an ISO or CE Marking isn’t something organizations can do on their own—it requires the expertise and oversight of accredited auditors, who represent a seal of trust and competency in the process of getting the standard.

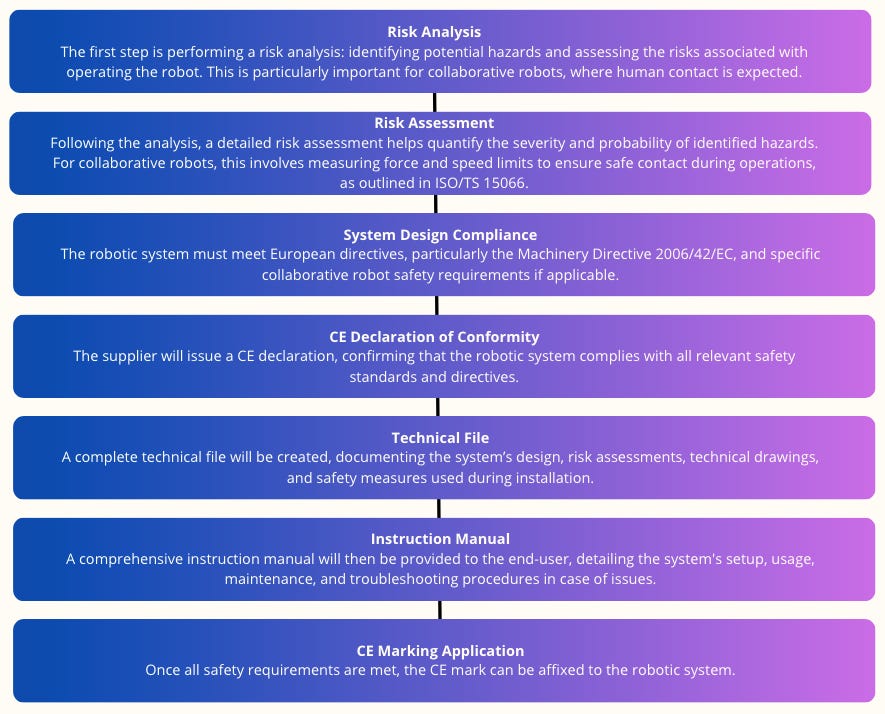

The steps to follow are as listed:

The Seal of Trust of CE and ISO Standards

By adhering to these standards, companies can ensure safety, efficiency, and interoperability across automated systems, including in collaborative workspaces. This not only builds trust with clients and stakeholders, but also positions the company as a responsible and reliable provider of safe robotic solutions.

More on the subject:

Cobots in Manufacturing - While cobots are currently only taking a small part of the robotic market at present, predictions are indicating that by 2025, cobots will account for 34% of all robots sold on the market.

Industrial robots vs cobots - Industrial robots have dominated the automation of industries for decades. Cobots, on the other hand, really started to take off in 2008. So, what is the difference between the two?